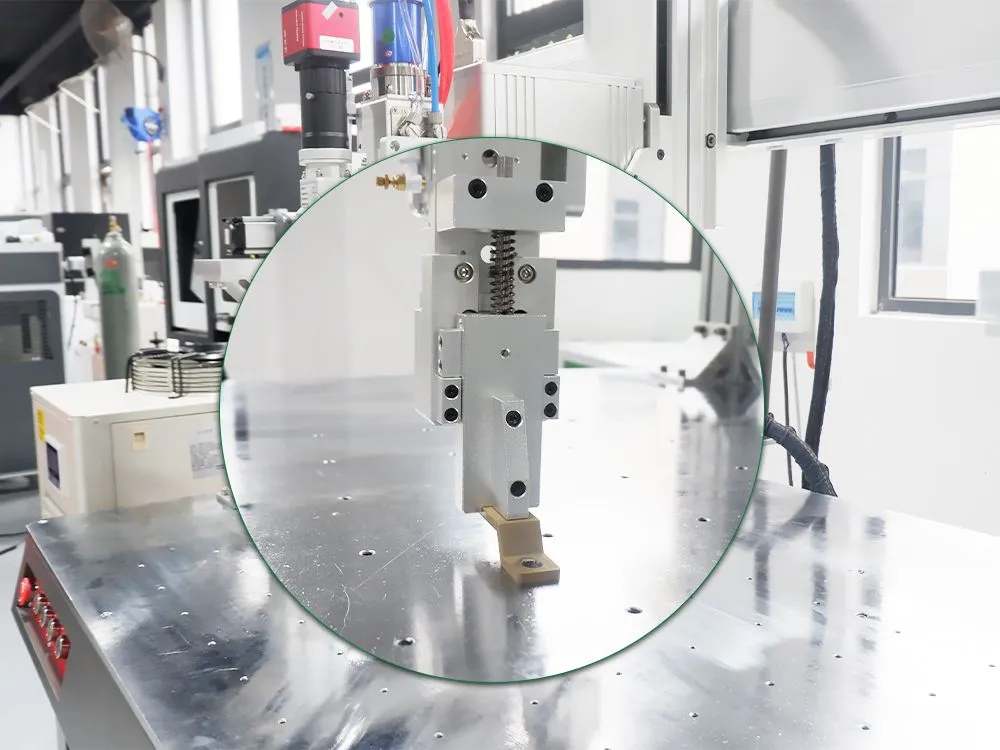

Parameters

| MODEL | HTW1500/HTW2000/HTW3000 |

|---|---|

| Power | 1500w/2000w/3000w |

| Pulse width | 0.1-20ms |

| Laser power | 2000W |

| Frequency | 0-100HZ |

| Wavelength | 1064nm |

| Solder joint size | 0.2-3.0mm |

| Protective gas | N2 gas |

| journey | 1000x600x600x300/400mm |

| GPS | CCD |

| cooling method | water cooling |

| Cooling system | air cooling |

Demonstration Video

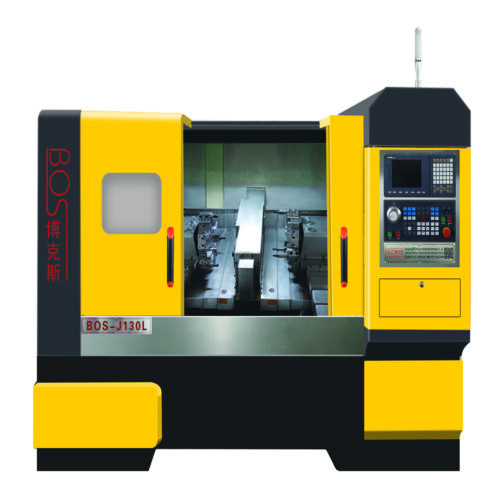

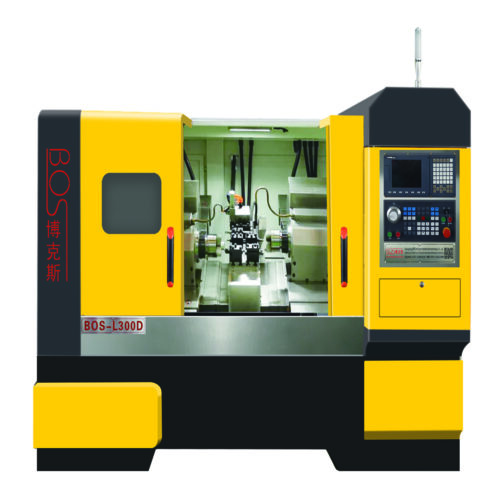

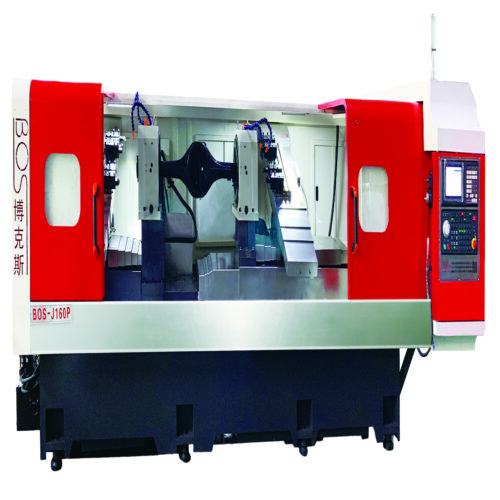

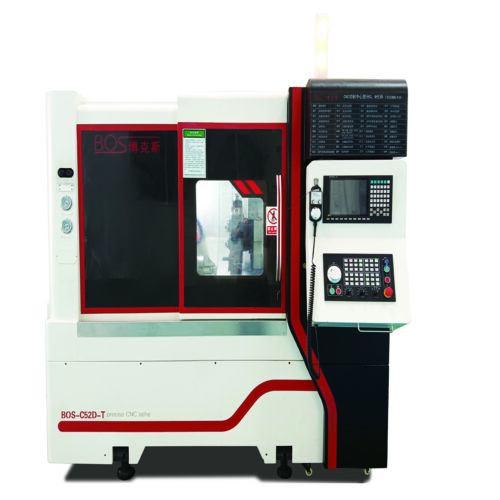

Double Head CNC Lathe Advantages

- Enhanced Productivity: A double head CNC lathe allows you to perform simultaneous machining operations, significantly reducing production time and boosting overall productivity.

- Precision Engineering: These machines offer exceptional precision and accuracy in machining, ensuring high-quality finished products with tight tolerances.

- Cost-Efficiency: By streamlining production processes and reducing setup times, double head CNC lathes contribute to cost savings in the long run.

- Versatile Machining: These lathes can handle a wide range of materials and complex part geometries, making them versatile for various industries.

- Reduced Labor Requirements: With automated operations, you can reduce the need for manual labor and minimize the risk of errors.

- Consistency: CNC technology ensures consistent and repeatable machining results, eliminating variations between batches.

- Optimized Space: Double head lathes offer dual functionality within a compact footprint, saving valuable floor space in your workshop.

- Quick Tool Changes: Tool changeovers are efficient, allowing for rapid adaptation to different machining tasks.

- Remote Monitoring: Many CNC machines come with remote monitoring capabilities, enabling real-time tracking of production and maintenance needs.

- Longevity: These machines are built to withstand heavy usage and are known for their durability and longevity.

- Competitive Edge: Investing in advanced CNC technology gives your company a competitive edge in the precision machining market.

- Excellent Finish: Double head CNC lathes can achieve superior surface finishes, reducing the need for additional post-processing.

- Adaptable for Complex Parts: They excel in handling complex part designs, including intricate contours and fine details.

- Energy Efficiency: Many modern CNC lathes are designed with energy-efficient features, helping you reduce operating costs.

- Technical Support: Reputable manufacturers often provide comprehensive technical support and training, ensuring your team can maximize the machine’s capabilities.